Created waste during the production process is a major issue for the Dairy Industry. It negatively impacts not just profits, but the quality of the end-product, and customer satisfaction. Customers want a high-quality, fresh product that is reasonably priced. Without minimizing waste during production, a manufacturer will never be able to maximize quality and value.

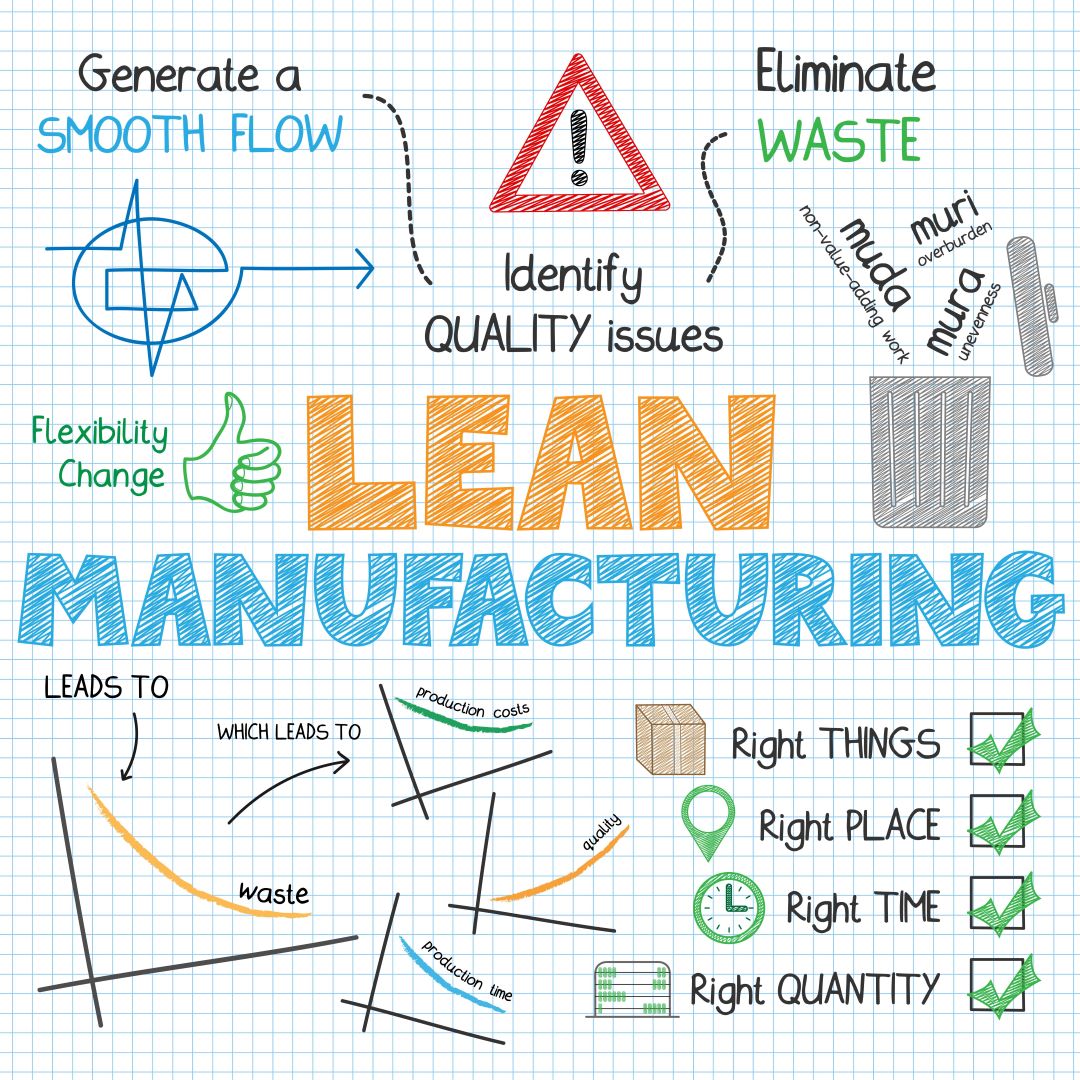

To combat the production waste issue, companies are adapting and using lean manufacturing methods into their dairy manufacturing process. Lean methods can help manufacturers increase profits and minimize waste, which helps to improve customer satisfaction. More specifically for dairy manufacturers, three lean tools can make a significant difference: Value Stream Mapping (VSM), 5S of lean manufacturing, and Jidoka.

Using Lean to Reduce Waste in Dairy Manufacturing

Lean methods have been used in manufacturing production for decades, first brought to attention in 1988 by John Krafcik in his published article, “Triumph of the Lean Production System.” (You can read the original 1988 article here.) This legendary article was the modern gateway to manufacturers understanding the benefits of using lean principles in production. When the book, “The Machine That Changed the World,” by Womack, Jones and Ross was published in 1990, the lean method really took off and became a common part of the modern factory.

Today, dairy manufacturers can use lean principles to focus on the way employees and managers work together to reduce waste and maximize efficiencies.

Create a Value Stream Map to reduce dairy manufacturing waste

The lean Value Stream Mapping (VSM) tool helps managers create a visual map of the inventory and components needed to reach production goals. It can help redesign a dairy manufacturer’s production methods to create maximum value.

To complete VSM, every step of every manufacturing process must be evaluated, along with recording the speed and volume of product that transfers from one step to another. Combined with lean principles, VSM can clearly show where processes are slow, interrupted, or inefficient, along with bringing to light where product defects originate. All of this gives dairy manufacturers a clear view of where waste is occurring, and then take steps to eliminate it.

For example, the VSM process may reveal that a machine was leaving residual milk products in piping before cleaning. Once identified, managers can decide whether the machine needs to be recalibrated, or if it was the result of human error, such as the machine being shut down too early.

VSM is also useful for continuous improvement—one of the top goals of lean methods. How and where to improve will become clearer and clearer once lean methods are used. This will lead to more profit, a better end-product, and a more satisfied customer.

Use Jidoka automation and human touch to fix errors

Jidoka, the Japanese word for automation with a human touch, is the method developed by the Toyota Production System (TPS) that uses advanced technology to prevent product errors during manufacturing.

Using this method, mistakes made during dairy manufacturing can be automatically detected so they can be immediately fixed. The highly advanced equipment that is used in automation can analyze and compile data so that manufacturers study and continuously improve their manufacturing methods. Automation also creates a standardized process within the manufacturing process that will further enable a facility to decrease waste and increase efficiency. These mistakes can also be analyzed to figure out where mistakes are most likely to occur and how to stop them from happening in the future.

Reducing dairy manufacturing waste with 5 S’s methodology

Based on five Japanese words, the 5 S’s of lean manufacturing can help dairy manufacturers reduce waste and maximize efficiency.

The 5 S’s are:

- Seiri—sorting

- Seiton—straightening

- Seiso—systematic checking/cleaning

- Sieketsu—standardizing

- Shituske—sustaining

Each step guides stakeholders through a comprehensive look at everything in a space. This helps decision-makers understand what is necessary and what is not. The 5S methods help put everything in order—cleaning—and putting in place processes and procedures to perform the same tasks on a regular basis to ensure quality and efficiency.

Using the step-by-step 5S method helps manufacturers significantly improve plant management, worker morale, work speed, quality, and risk management.

Learn How to Use Lean Manufacturing to Maximize Efficiencies and Minimize Waste

Dairy Manufacturers have learned that using lean manufacturing can help them reduce waste and maximize efficiencies but focusing on the way employees and managers collaboratively work. Lean methods give manufacturers a better understanding of what happens on the production floor, from human performance to machine performance. Combined with Worximity’s Smart Factory Analytics, managers get real-time data to make better decisions and get the best results.

See what lean manufacturing can do for your company. Worximity’s Lean Manufacturing eBook gives you everything you need to see how smart automation can get.

In addition to more information about VSMs, the 5 S’s, and Jidoku, you’ll learn:

- The five types of waste

- The 3 M’s of lean manufacturing

- The Kanban scheduling system

- Poka-Yoke mistake proofing

Get started—download our Lean Manufacturing eBook now.